Cleanroom Facility Programming

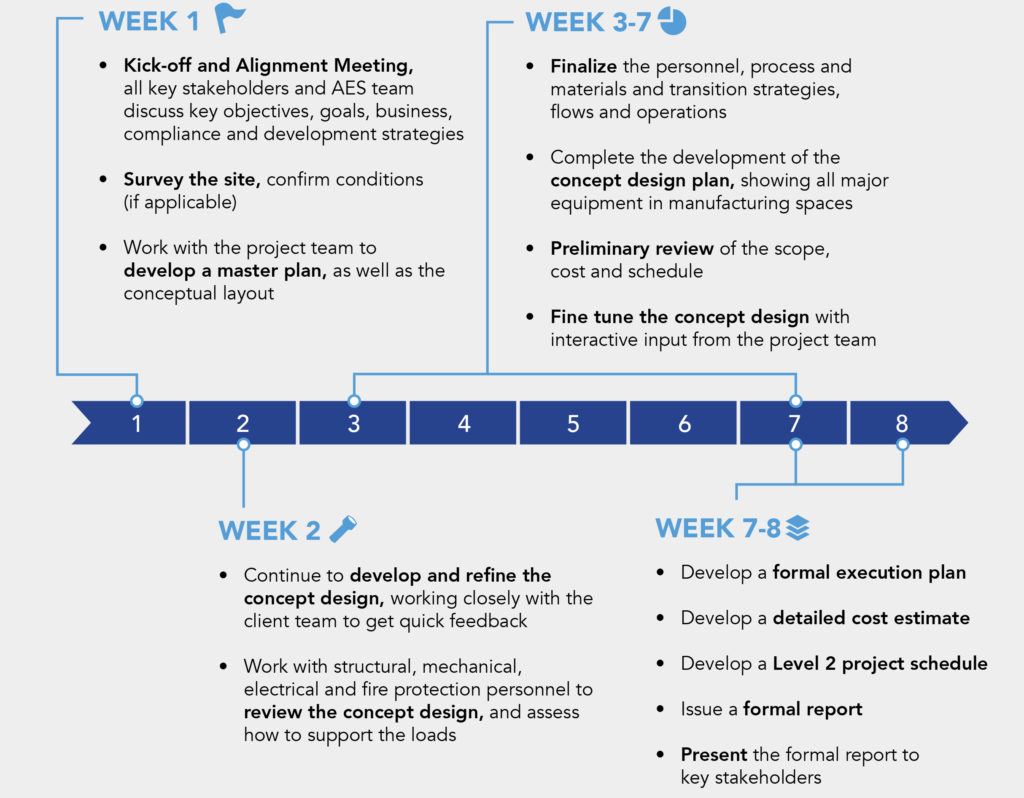

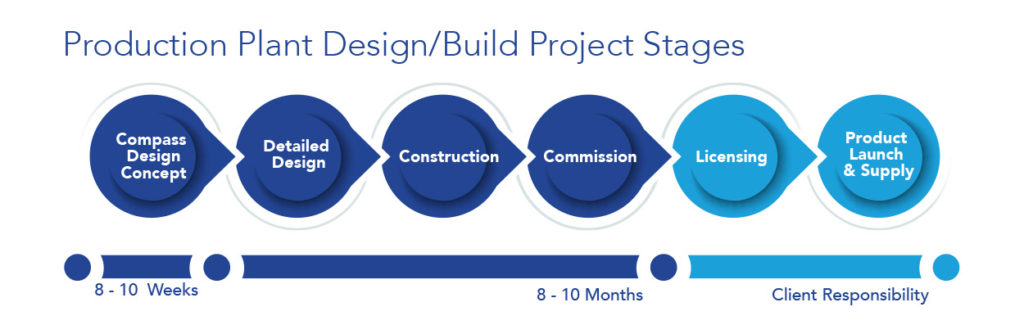

The AES Compass program is designed to help you conceptualize the critical parameters of initiating your cleanroom construction project and extract the technical and strategic factors that will lay the foundation for an efficient, detailed cleanroom design.

The Right Direction, From the Start

With over 35 years of experience, we have witnessed the changes in regulations, as well as the challenges clients face in getting products to market faster and more efficiently.

We bring that expertise into the facility programming process, identifying each project’s unique content and compliance requirements to ensure proper design and avoid scope creep from the start.

Why Choose AES Compass?

The success of any cleanroom project hinges on accuracy and foresight before any design has been put to paper. Not only must your cleanroom facility be compliant to both regulatory requirements and the strict environmental criteria of your manufacturing process, it must also be built on-time and on-budget.

Undiscovered user requirements and space issues can derail a cleanroom construction project, creating unforeseen obstacles and delays that can cost you money and valuable manufacturing time.

The AES Compass program is designed to mitigate these risks by uncovering potential hurdles upfront and creating a plan to circumnavigate them ahead of the design process.

With Compass, we combine our facility expertise with your processing expertise to develop a robust conceptual design package for your cleanroom facility that fully defines the project’s expectations and requirements, and helps eliminate project delays.

The net result is a package of deliverables that are both technical and commercial in nature – focusing not only on the compliant design of the facility, but also on its cost, schedule, and execution strategy.

Compass Program Deliverables

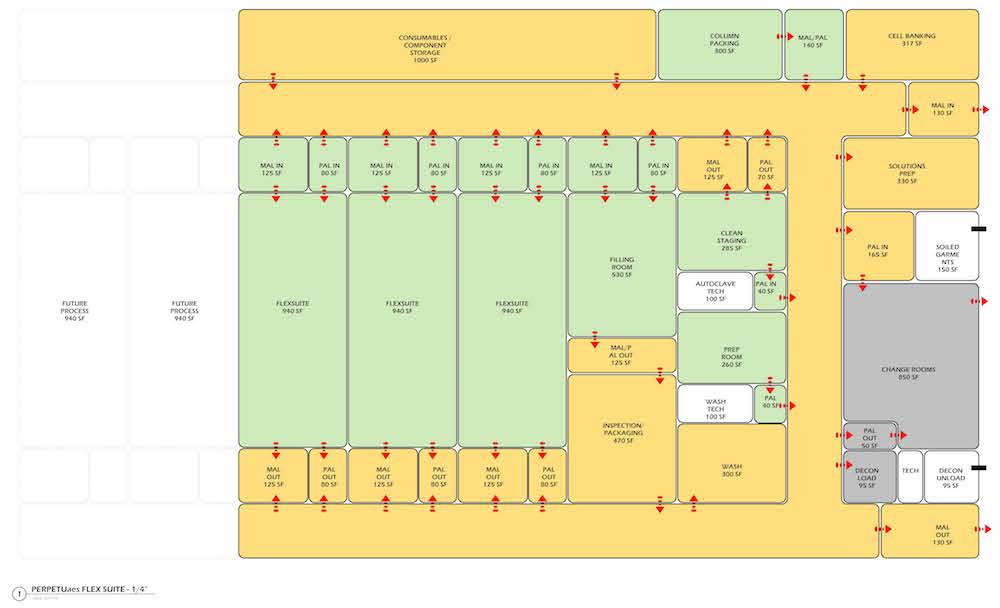

Through the Compass programming process, AES will develop an overall master plan for your facility, showing major operations and telling the story: “Where are we now, where are we going, and how will we get there?” — including a 1-, 3-, and 5-year development strategy based on your business objectives.

These deliverables will enable you to acquire quantitative data for designing and building your facility (scope, schedule, and cost), as well as prepare for strategic and regulatory reviews and capital project funding requests.

Scope

Scope

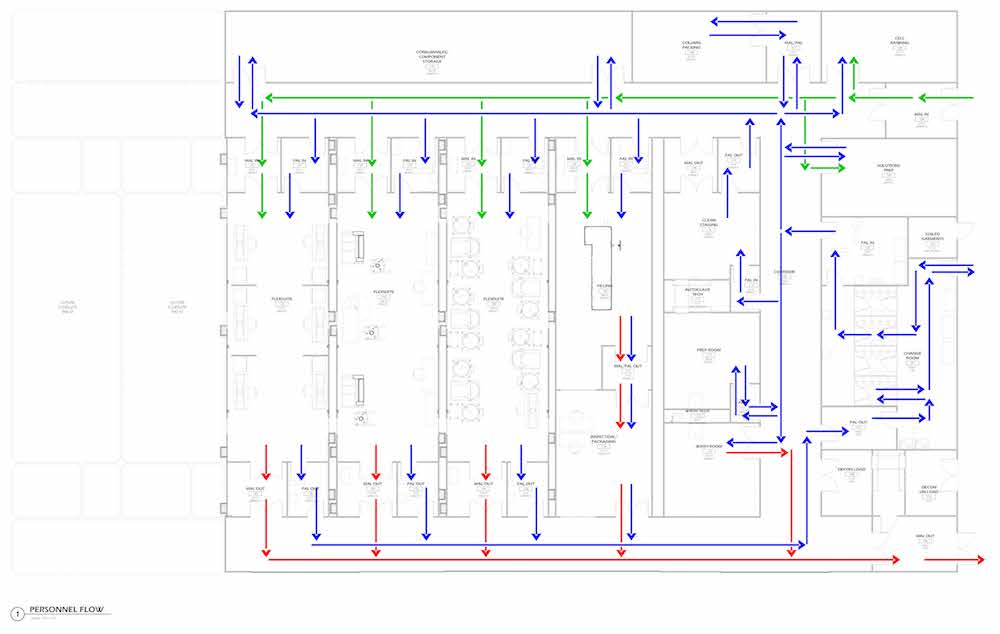

Definition and alignment of process, facility, and GMP commercial supply capacity requirements.

- Classified space programming

- Operational flow design layout

- Mechanical (HVAC) design layout

- Facility finishes & functionality

- Regional compliance assessment

- “Type C” FDA meeting content

Schedule

Schedule

Start-to-finish integrated schedule.

- Critical path analysis

- Equipment qualification

- Installation & construction

- Commissioning

Cost

Cost

Comprehensive cleanroom design/build estimate and capital project funding data content.

- Breakdown by major categories

“AES had a tall order on this project with a tight timeline to meet our Bioreactor installation date and the team has met that challenge. Even when presented with coordination issues Sergio and his team have stepped up to the challenge each time with quick and efficient solutions to maintain schedule and quality.”

– Arun S.