Lean is the core of what we do AES, and I want to take this opportunity to explain how we do it.

Lean Construction, as a buzzword, gets a lot of play in the cleanroom industry for good reason. It is an idea that got its start with Toyota in the 1950s to maximize efficiency and eliminate waste in production.

In practice, Lean Construction is a holistic approach that looks at efficiencies across the entire process of building, from architecture to engineering design; from the team hammering nails to the weakest link in the supply chain—Lean encompasses the entire process, and each component of the Lean process maximizes the efficiency of each individual construction project.

As I said, Lean is at the core of what we do at AES, but we do not practice Lean Construction.

Our Faciliflex Module and Faciliflex Express cleanrooms are never built, so we cannot call it Construction. Every component of our Faciliflex cleanroom product lines is manufactured in the United States at our clean, efficient factory and installed on your site.

We practice Lean Installation.

What that means for you is that we take out almost all of the risks to your commissioning and manufacturing timeline before our modular cleanroom walls, ceiling or HVAC components even make it to your site.

Everything in its Place — 5S in Practice

One of the ideas we have adopted from the Lean concept, particularly in terms of cleanroom manufacturing is what is called 5S—it is a system of workplace organization that, like Lean Construction itself, has Japanese origins. The five “S” words that define the system are Japanese, but they are often translated to English as “sort, set in order, shine, standardize and sustain,” which are all practical dictates to seek efficiency in the workspace.

For the manufacturing floor, that means everything is laid out in a way so that our workers have all the tools and parts they need when they need it. It is also a mental construct that dives continuous improvement for safety, quality, and productivity both in our factory and at your site.

On site, our 5S program is tailored to the needs of each project, according to Lean principles, and is developed through interaction and planning with appropriate stakeholders. There is no one-size fits all approach, and we look at each project to see how we can integrate with other schedules.

The Zone Offense

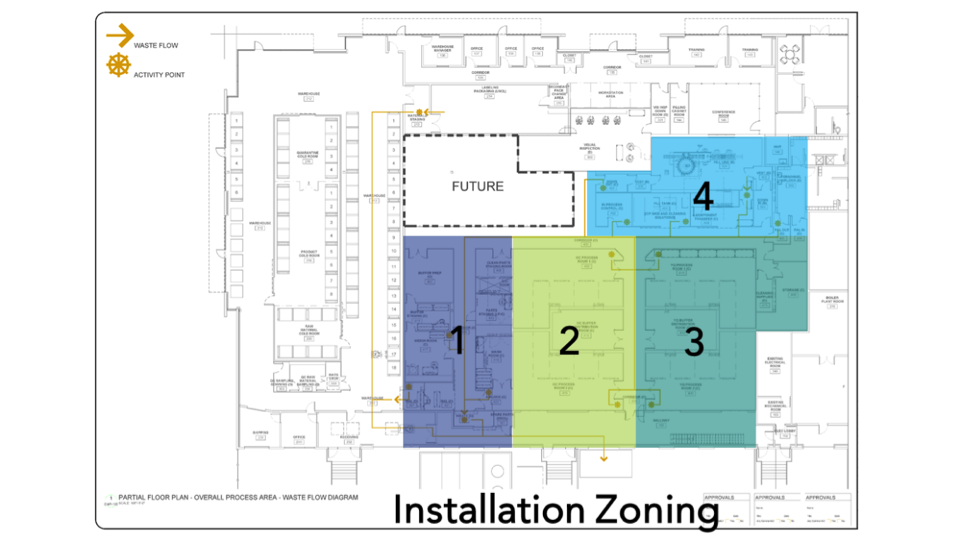

The figure above provides one example of how we put 5S into practice recently in a 22,000 square foot facility for a large plasmid manufacturer. You will see that we designate areas as different zones. We hang and install out the ceilings first, which allows us to get out of the way while other trades and services work.

Unlike stick built cleanroom construction, which requires contractors to build on-site, we manufacture everything in our Suwanee, Georgia, plant and ship to site on an exacting, just-in-time schedule. Everything is standardized—again, an important 5S concept—and any required ceiling or wall aperture is created at the factory, not at the site. We utilize a separate staging area nearby to unwrap and prep each module component prior to installation. Each night, the staging area is sorted out, cleaned up (shined!) and set for the next day’s work, which helps ensure everything flows according to the timetable.

This level of site organization and coordination with other trades are crucial to ensure there are no gaps or conflicts. In fact, in this example we actually shaved off about 4-6 weeks from the construction timetable by simply coordinating our installation with the other trades.

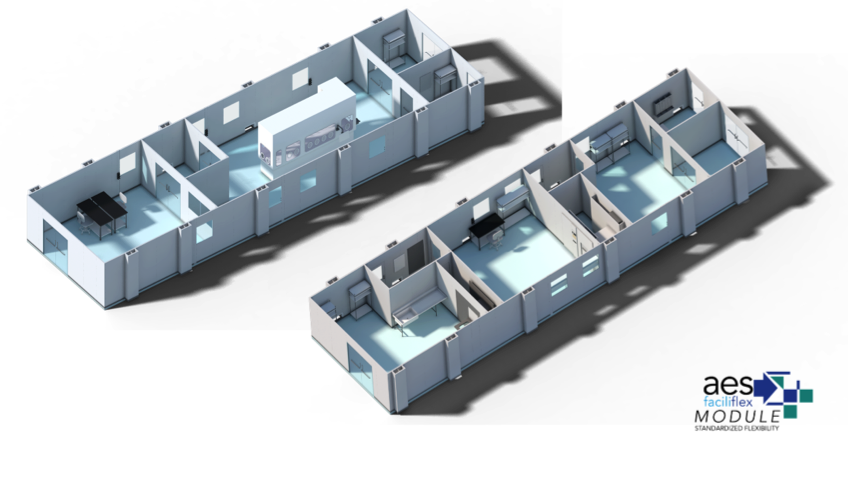

Faciliflex Module

Perhaps the ultimate expression of the 5S Lean Installation philosophy is our Faciliflex Module line of products. Facilliflex Module offers the ultimate flexibility in cleanroom design—pre-configured, modular “baseblocks” that allow you to mix-and-match all the components you need for your next cleanroom facility—from manufacturing to custodial locker rooms. Standardization here, once again, will offer greater efficiencies, both during installation and after commissioning.

Pull and Takt Planning

The core notion of Lean is to eliminate every kind of waste. 5S is one way we eliminate waste for individuals, but for overall coordination of a project—to eliminate waste in the timeline–we also incorporate Pull and Takt Planning.

Pull planning is a concept we use based on the Last Planner System® to create a comprehensive, integrated plan for each phase of an installation. Takt Planning is similar, but we break the entire process up by zones that allow us to manage the workflow of each trade involved on the job site. The idea is to keep the project moving forward while making sure nobody gets in the way of anybody else.

In the Flow

I want to introduce one last concept that isn’t really part of Lean methodology, but perhaps should be: Flow.

It is a psychological term, meaning that you feel immersed in what you are doing and energized. It is the Flow state; being in the zone.

The way I see it, I know Lean is working when everyone involved gets in the Flow state. Everyone works more efficiently when they can focus on the task, and all of the Lean tools we use are just a means of getting there.

At AES Clean Technology, we have established what I believe is an extraordinary process of managing the manufacturing and installation of Faciliflex Cleanrooms. For our customers, this means a smooth installation process. We practice our flow so that you can practice yours: delivering lifesaving therapeutics to those who need them.

About Chad Smith

Chad has more than thirteen years of Design/Build experience in the life sciences industry. During this time, Chad has developed a customer focused approach with strong communication skills. As a Project Development Engineer, Chad enters the flow state while ensuring all aspects of the AES Design/Build team are moving in one direction to meet the needs of our clients. It is his super power.