It takes foresight to build a cleanroom. Not just the vision required to develop a new therapeutic and bring it to market, however. Cleanroom design and cleanroom installation requires insight into your manufacturing process, but also the global awareness of how to install a complex modular cleanroom system within budget.

At AES Clean Technology, the task of providing customers with a clear vision for cleanroom installation falls to BIM Manager, Eric Eckels.

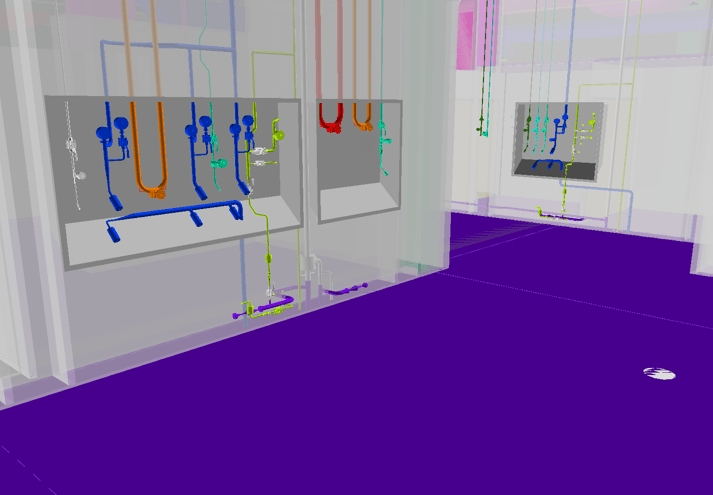

His team implements BIM – or Building Information Modeling – to review a cleanroom design in a virtual setting in order to deconflict a project’s construction timeline. Depending on the host facility, a new cleanroom provides many challenges as different trades and disciplines attempt to operate within a given space. That is particularly true in constrained physical environments, such as older host facilities or sites immediately adjacent to labs, offices or other facilities. A data enriched model of a cleanroom project reduces risks to both budget and timeline.

After

After Before

Before“Our most important role for BIM is to predict and mitigate potential clashes between the installation team, the systems engineering, and all of the trades that will be present on site,” said Eckels. “Discovering planning conflicts through our models ensures that everybody avoids creating conflict on site.”

According to Eckels, BIM generates a data enriched model to graphically represent the holistic assembly of the entire cleanroom system for each phase of the project. This includes the quantity, size, shape, location, orientation, and interfaces with other building systems. AES leverages its BIM design model for documentation to reflect the scope, detail and quality of the design to ensure accuracy and proper coordination.

“BIM implementation allows AES to deliver a high quality project within budget,” Eckels said, “We see trouble coming and we’ll stop it in our models long before it can get to your site.”

The AES BIM Approach for Cleanroom Design

- Data Enriched Model: combines layers of quality information over cleanroom project designs to deliver comprehensive planning results.

- Coordinated Design: removes the obstacles for detailed planning and project execution.

- Accurate Documentation: provides scope, detail, and quality information to ensure accuracy and proper coordination.