In the 1980s, Lionel Ritchie extolled the benefits of dancing on the ceiling. For safety reasons, we will ask you to refrain from dancing on the AES modular cleanroom ceiling system—walking, however, is just fine. In Part 1 of our cleanroom ceiling blog series, I will tell you why the AES Marquee Walkable Ceiling system saves your organization money while providing a superior fit and seal for your cleanroom construction needs.

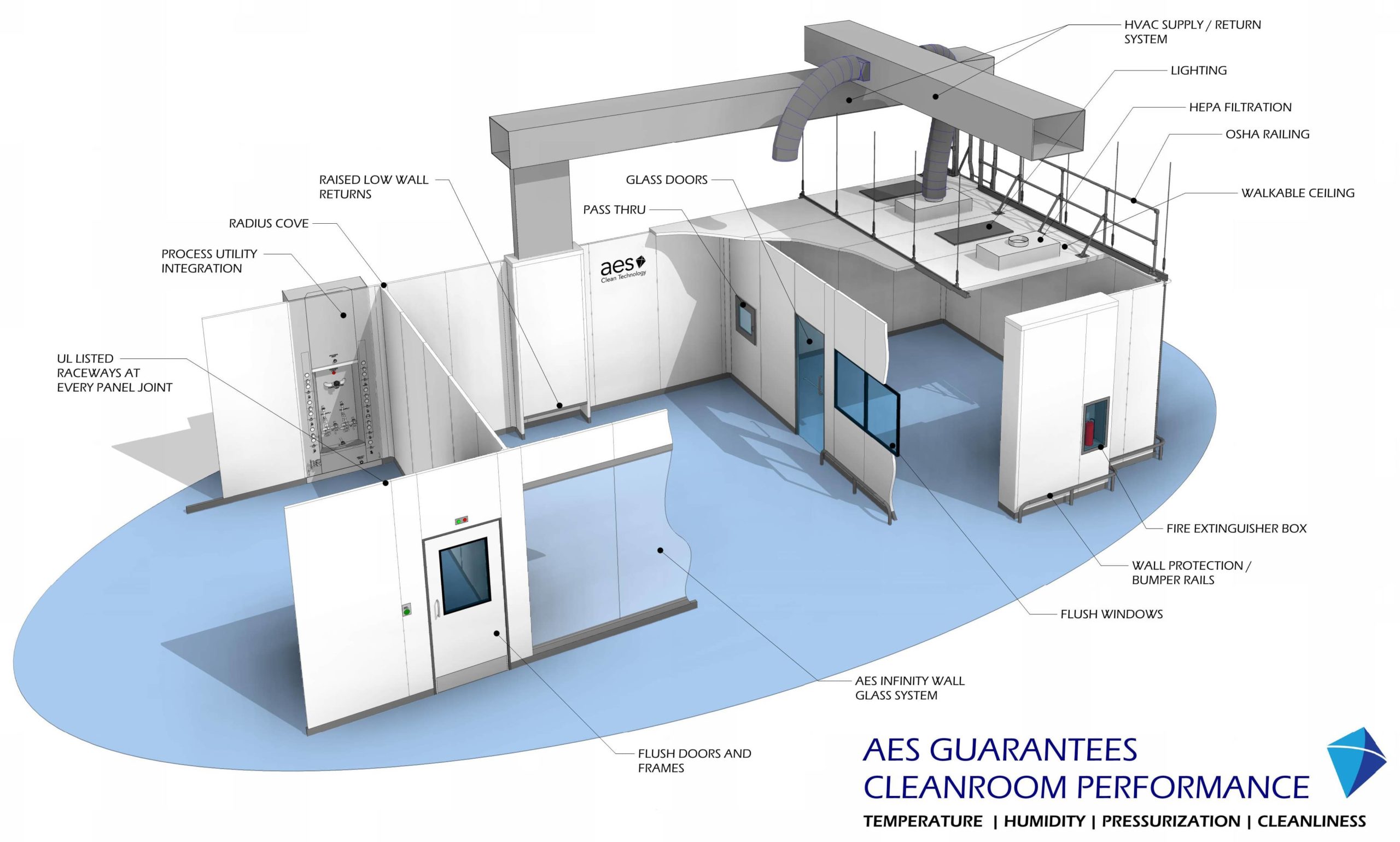

Our AES Marquee Walkable Cleanroom Ceiling System is a crucial part of the AES modular system overall, including all of our Faciliflex cleanroom offerings. The ceiling, itself, has an important job to do helping to maintain the integrity of the cleanroom environment while keeping the mechanical and other infrastructure components out of view.

How AES Marquee Walkable Ceilings Work

Installation begins [Figure 1] by hanging drop rods from the building structure. We place the rods in rows, typically spaced on 10-foot centers, with each rod in a row spaced about 4 feet apart. As you’ll see, this will provide a lot of room for maneuvering.

The rods tie into flush beams: architectural grade aluminum beams formed into an upside-down “T” shape. Once our cleanroom construction experts precisely level out the beams by adjusting the turnbuckle connection to the rods, our installers can then simply slot each panel into place. This system eliminates the time-consuming need to hang and level each panel separately. Similarly, the cleanroom wall panels tie in neatly and cleanly into the cleanroom ceiling panels, without ever compromising the environmental seal of the cleanroom.

The AES cleanroom ceiling panels, themselves, are engineering marvels. Our ceilings are comprised of extraordinarily strong, non-combustible aluminum framed panels with an aluminum honeycomb core. The core is covered by galvanized sheet steel and coated with a uPVC finish. The resulting panels are relatively light and incredibly solid.

We manufacture and assemble each cleanroom panel to order at our plant in Suwanee, GA. While our cleanroom installers can adjust on site for late changes to openings and utilities, most of these cleanroom design modifications are made in a controlled environment in our manufacturing facility.

Like our wall panels, installers just need to peel off the protective film and begin putting pieces into place. The result is a clean, debris-free worksite.

One Overlooked Way AES Marquee Walkable Cleanroom Ceiling Systems Save You Time (and, Money)

Constructability. Timetable management. Whatever you call it, there is a lot of risk in your schedule in managing the trades that need to interact at the site of your future cleanroom. This is one overlooked way that the AES Marquee Walkable Cleanroom Ceiling System can save time on your schedule.

We can install our hanging rods before anyone else comes on to the site. This provides time and space for all the other trades—including fireproofing, mechanical, plumbing, and electric—to get what you need done before cleanroom installation is set to begin. The result is an organized, manageable workspace that, as you can see from the pictures, is almost as clean as the space beneath the cleanroom ceiling panels.

The more we consider it, maybe we’ll take back what we said, our cleanroom ceilings are worth dancing over, if not on.

In our next AES cleanroom blog post, we’ll share with you the AES secret weapon—Litebeam, our proprietary cleanroom lighting fixtures built to be fully integrated into the AES Marquee Walkable Cleanroom Ceiling System.

6 things to know about AES Marquee Walkable Cleanroom Ceilings:

- Built for live loads

- Accelerated schedule – allows for concurrent activities above/below ceiling during installation phase

- Pre-engineered for predictable, repeatable quality

- Pre-manufactured, minimizing ceiling hazards associated with stick-built construction

- Designed for easy maintenance and inspection

- Integrated seismic bracing, available when required

Please feel free to contact us using the below form for further details and specs on the AES Profile Wall & AES Marquee Walkable Cleanroom Ceiling System.

About the Authors:

Chris Hohn has been with AES since 2016, starting his career as an estimator, and transitioning to a project development engineer role in 2019. Chris studied civil & architectural engineering at Drexel University and was always fascinated by unique construction projects and materials. In early 2020, Chris opened the AES west coast office, located in Irvine, California.

Matthew Korkuch is a project manager for AES. He has worked in the construction department since 2012 in a variety of roles. In March of 2020 Matt relocated to AES’ Irvine, CA location in order to better serve west coast clients.